Underwater & Dam Inspections

Underwater & Dam Inspections with Multi-Sensor Technology

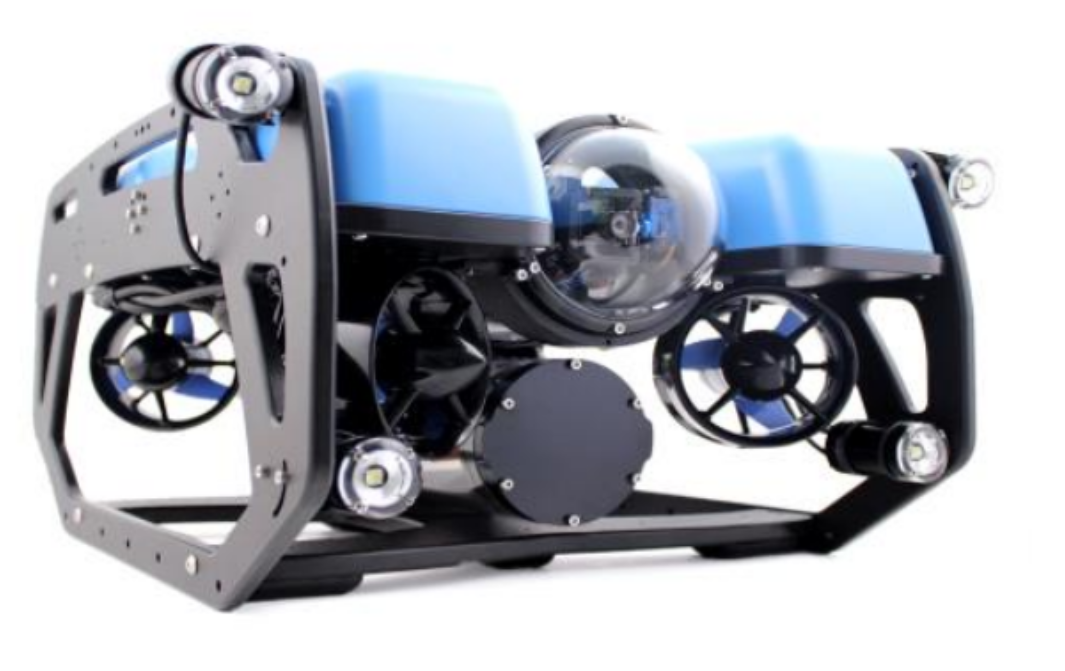

SewerVUE's Submersible Remotely Operated Vehicle (ROV) inspection system presents a comprehensive solution to address the multifaceted challenges encountered in the realm of pipe inspection. These challenges encompass scenarios where conventional drainage methods may not always be feasible and situations that necessitate remote access. SewerVUE’s underwater ROV offers a wide variety of inspection solutions. This ROV can inspect fully submerged pipes ranging from 13.5 inches and up. SewerVUE can equip this ROV with Ultrasonic thickness testing gauges to measure the wall thickness of metallic pipes such as steel, ductile iron and cast iron pipe.

For all other pipes and materials such as siphons and penstocks, the SSV can measure the internal geometry using state-of-the-art profiling sonar. The SSV can inspect up to 1 km from a single access point, with options to inspect up to 10 km in certain applications. SewerVUE makes use of unique inertial measurements to be able to create truly accurate digital doubles of these critical assets.

Jackson Lake Case Study The Multi-Sensor Approch

The focus of the inspection was an 18-inch steel Jackson Lake Dam outlet pipe. The inspection aimed to provide a comprehensive CCTV video assessment of the entire pipe's length, combined with wall thickness measurements at 5-foot intervals. SewerVUE's submersible ROV was inserted from the MH "Outlet" and inspected along the line for approximately 140 feet, after which it was winched back for extraction from the entry point on MH "Outlet." Total length of inspection was 126 Linear Feet.

The Jackson Lake inspection was performed using a submersible Remote Operated Vehicle (ROV) equipped with high-resolution video capabilities and an ultrasonic thickness testing probe. The inspection scope required ultrasonic thickness measurements at 5-foot intervals. To optimize the results, multiple passes of the entire pipe length were conducted. The initial pass was visual-only, followed by the ultrasonic thickness measurements pass, with the interval modified to 10 feet upon the client's request. Nevertheless, SewerVUE collected data at a closer interval of 5 feet during the return pass.

SewerVUE Technology

SewerVUE can tackle big jobs in some of the toughest places on Earth, and get actionable data quickly. Our methods are both accurate and cost-effective. By using remotely operated vehicles to gather data, these methods also eliminate the hazards of man entry surveying methods.

To discuss how SewerVUE can meet your specific needs, contact us today!