Large Diameter Pipe Inspection

Large Diameter Pipe Inspection with Multi-Sensor Technology

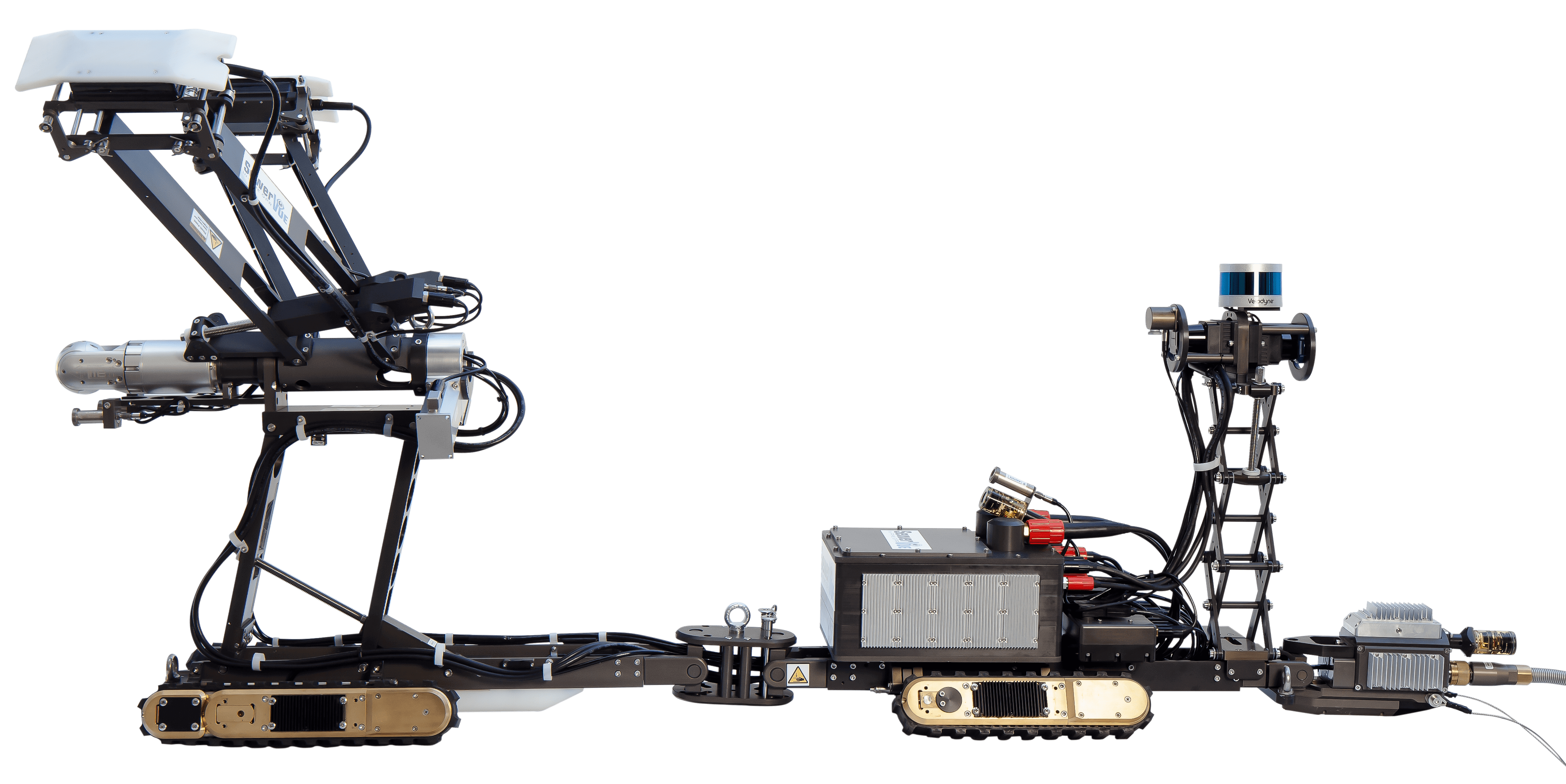

SewerVUE Technologies is a leader in multi-sensor condition assessments on large diameter pipes. SewerVUE’s approach to large-diameter pipe inspection incorporates a combination of several synchronized sensors: CCTV, True 3D LiDAR, 2D LiDAR, Sonar, and pipe penetrating radar to provide comprehensive insight into the condition of large diameter pipes.

With multi-sensor technology, our surveyors can detect the remaining wall thickness of a pipe, find defects and potential blockages, check deterioration levels, detect voids before they become sinkholes, and perform a collision analysis to make sure your rehabilitation efforts are not wasted.

Multi-Sensor Condition Assessment Features

SewerVUE has a range of floats and surveyors to help you gather the qualitative data necessary to make informative decisions on large-diameter pipes. To find out which solution would would best suit you, contact us today or click here to learn more about our products.

Hong Kong Case Study

SewerVUE's team travelled to Hong Kong to inspect a 7km long sewer tunnel. The tunnel, a 10-foot diameter reinforced concrete tunnel, had been in service for 15 years and had never been inspected. The objective was to assess the condition of the tunnel using a combination of CCTV and LiDAR.

Though it was a long day, SewerVUE completed the inspection in a single day, on budget. The results showed only a small number of structural defects.In large diameter pipes such as this one, CCTV is not particularly useful. However, combined with other sensor technologies, we delivered a detailed report outlining the structural and service defects in the Tolo Harbor TEES Tunnel.