The SewerVUE

Multi-Sensor Pipe Inspection Float

Integrated Sewer System Data Collection with Multi-Sensor Inspection

SewerVUE’s MPIS Float is a long range multi-sensor pipe inspection technology that provides a robust way to inspect high-flowing large diameter pipes. DataVUE sensor fusion software allows you to collect and export data with only 2 clicks.

Check out our brochure for additional information

Float Features

Description

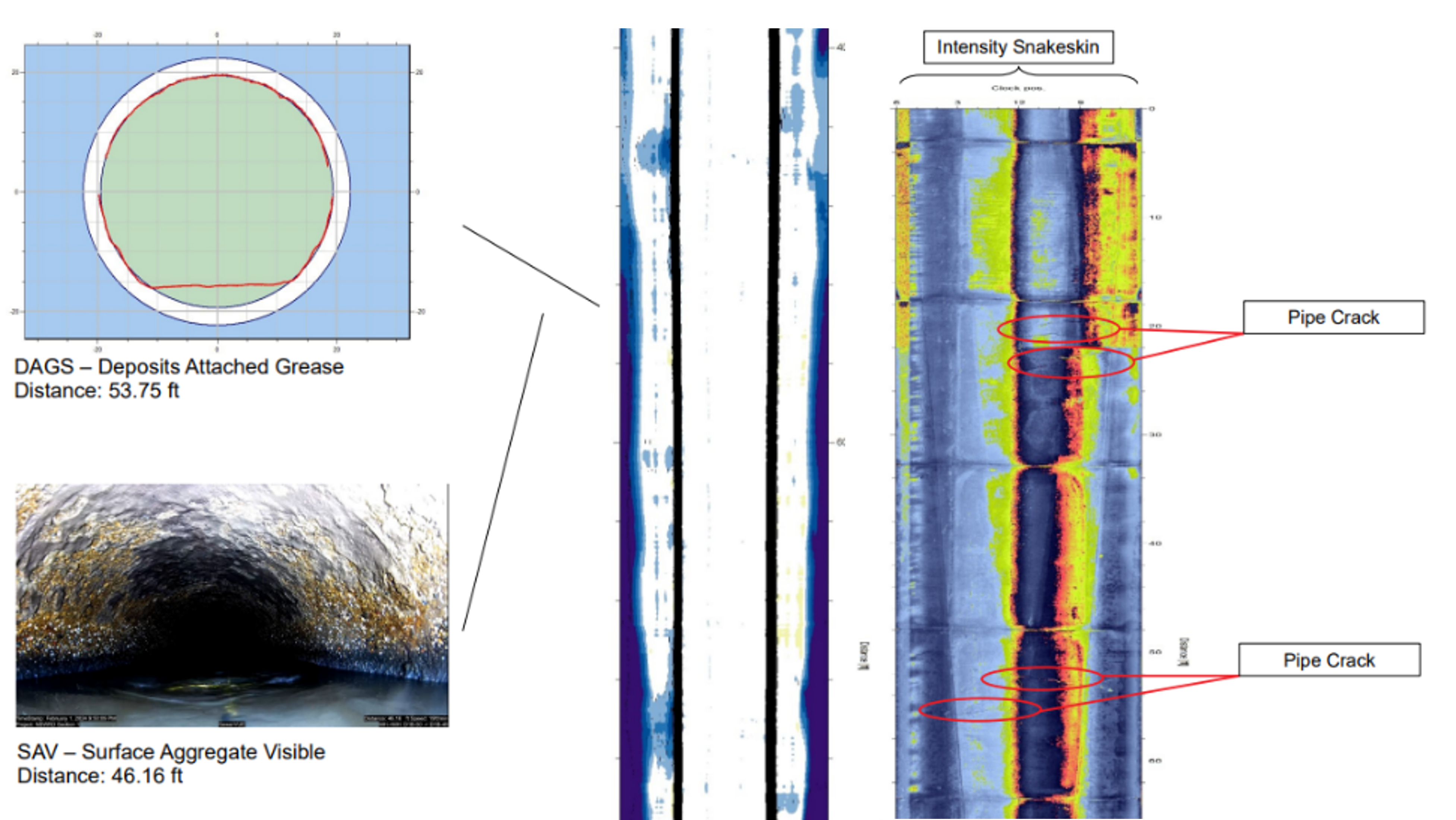

SewerVUE’s long range pipe inspection technology combines state of the art data collection and analysis with proprietary processing and software. SewerVUE's sensor inspection tools can be accommodated on any Float platform, ranging from HD-CCTV, accurate 3D LiDAR, and Sonar Imaging. Floats can be fully submerged in water and waste water. The sonar data provides pipe profile below the flow line together with sediment depth and volume. This can be combined with LiDAR readings to give a full view of the pipe.

Inspection reports provide integrated and quantitative corrosion and debris measurements, 360 degree virtual pan/tilt/zoom function, video, laser and sonar flats.

Easily visualize, verify, and record data with a click of a button with DataVUE sensor recording software, a user-friendly platform that anyone can use! View your data in real time and check all connectivity of your sensors.

Contact us for more information.

MSI Geometry Results

Utilizing orientation sensors for accurate scene placement, our system merges scans seamlessly through AI-driven algorithms. It identifies key features such as stains, joints, and cracks while enriching data with dense 2D information. By geo-locating using surveyed references and fusing sensor data, we generate precise 3D pipe measurements to construct a comprehensive digital twin. This model enables thorough assessment and evaluation of slip liner rehabilitation feasibility. By eliminating the need for repeat inspections through error correction and synchronized data collection, our advanced reconstruction algorithms deliver exceptional results without the interruptive "stop and scan" procedures, maximizing efficiency and ensuring optimal data quality.

Contact us for more information.