The SewerVUE

Asbestos Cement Pipe Scanner

Revolutionary Technology for AC Pipe Condition Assessments

SewerVUE Technology’s unique Pipe Penetrating Radar technology is now available for small diameter pipes. The Asbestos Cement Pipe Scanner (ACPS) provides critical, quantitative information about the condition of 250 mm (10-inch) asbestos cement and other non-ferrous pipes.

Check out our brochure for additional information

ACPS Features

Description

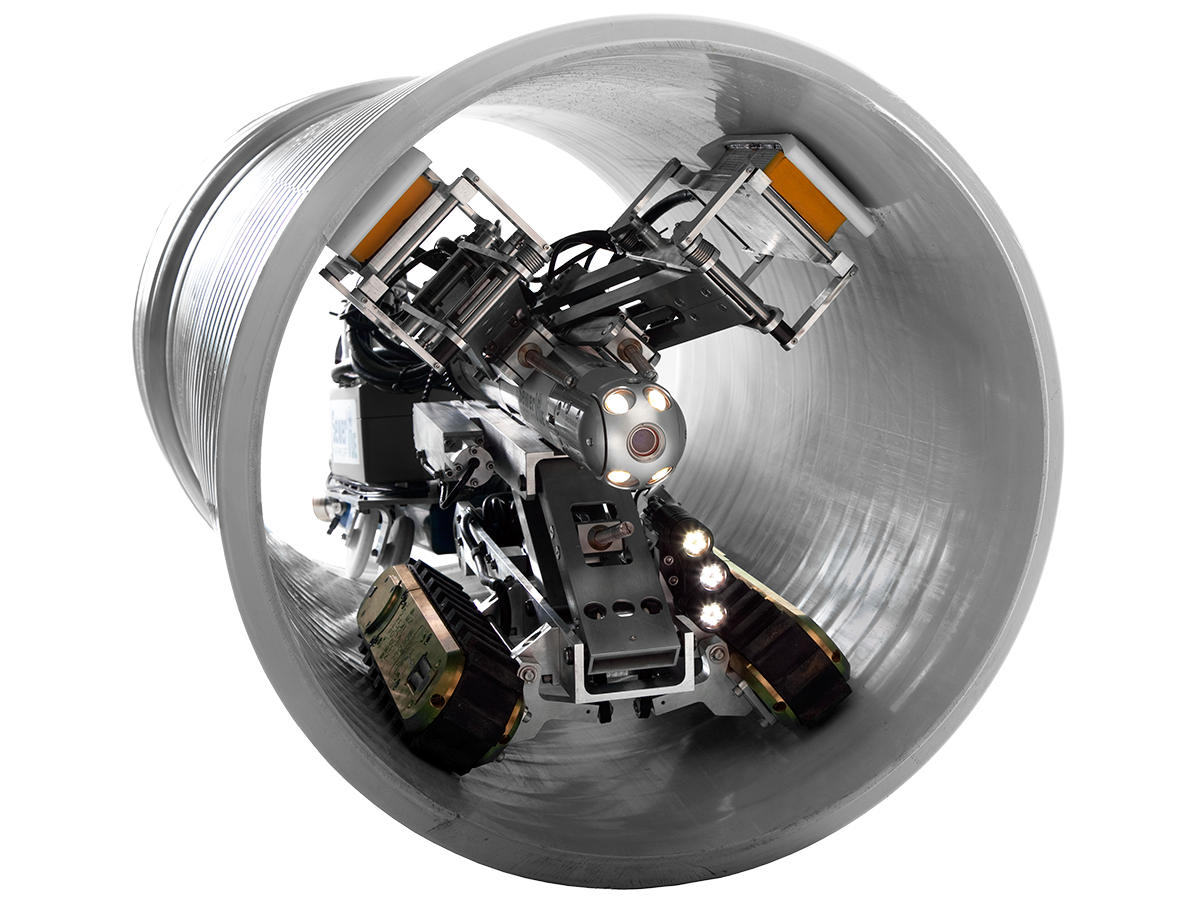

Introducing the Asbestos Cement Pipe Scanner (ACPS) by SewerVUE Technology, now available for small-diameter pipes. By using Pipe Penetrating Radar (PPR) technology, this innovative device offers critical and quantitative information about the condition of asbestos cement and other non-ferrous pipes ranging from 250 mm to 450 mm (10 inches to 18 inches) in diameter. This advanced scanner provides invaluable insights into the structural condition, potential damages, and deterioration levels of asbestos cement pipes, enabling proactive maintenance and informed decision-making.

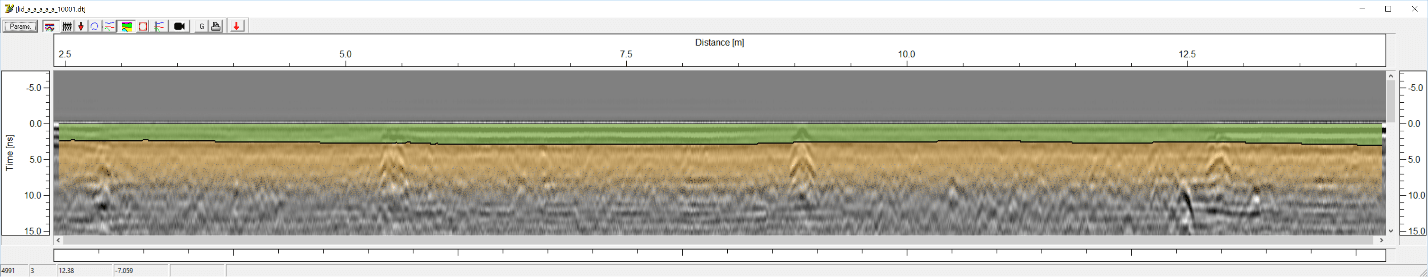

By utilizing state-of-the-art Pipe Penetrating Radar technology, the ACPS offers a non-destructive and non-intrusive method of evaluation. It emits electromagnetic pulses that penetrate the pipe wall and bounce back, providing accurate data on pipe thickness, diameter, defects, and potential blockages. This detailed information helps prioritize maintenance efforts, prevent costly repairs, and ensure the longevity and reliability of your pipeline infrastructure.

Contact us for more information.

The Problem

Asbestos Cement Pipes

Between the 1930s and the 1960s, a new type of material emerged as a popular choice for newly laid pipelines: asbestos cement (AC). Over the course of several decades, thousands of miles of AC pipe were laid across North America to be used as water and sewer lines. It is estimated that as much as 12-15% of all in-service potable water mains in North America are constructed from AC pipe. The useful life of these pipe was estimated to be about 50 years. Since then, studies have shown that the useful life is actually more like 60-70 years on average. In either case, thousands of miles of AC pipeline are nearing the end of their useful life. Asbestos cement pipe failures are on the rise, especially in the western and southwestern United States.

Options for managing this problem are limited; effective options even more so. Of course the obvious choice may be to simply look at the average life of AC pipe, and replace pipes as they near that age. While that may “work,” it certainly isn’t efficient or cost-effective. Many AC pipes have been shown to be in great shape, even at 70 years old.

The Solution

Preventative Maintenance

Preventative maintenance is the method of accurately identifying which pipes have reached the end of their useful life, and replacing them before catastrophic failure occurs. This is best done by developing a predictive model of the pipe’s useful life. Creating an accurate predictive model is, of course, the challenging part. Small-diameter pipes can generally only be inspected with CCTV, which has limited benefits in trying to determine if a pipe truly needs replacing.

The value in SewerVUE’s PPR condition assessment is that localized measurements of pipe wall thickness and void detection can provide a quantitative base to develop models of the remaining useful life of the asset to predict failure and determine the optimal timing for rehabilitation.

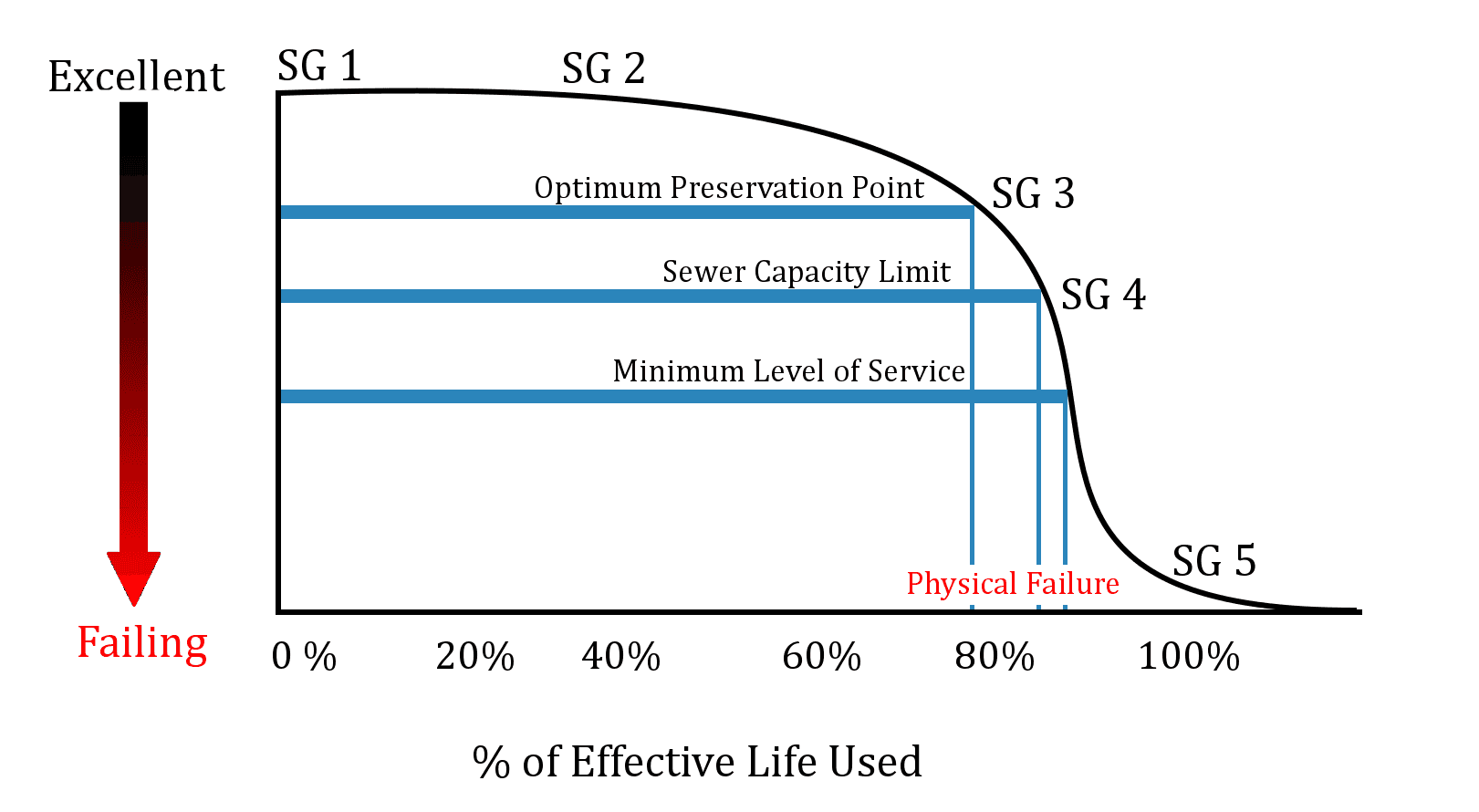

Optimum Preservation Point

By the time an AC pipe has deteriorated to the point where it is assigned a Grade 4 or 5 through qualitative methods, the pipe has progressed to failure or near failure status. An objective of the condition assessment process is to identify pipes in the earlier stages of deterioration. Asset inventory identified at the early stage of the deterioration curve can be rehabilitated in a cost efficient manner.

For example, a sewer main rehabilitated with a structural grade of 3 could be designed as a partially deteriorated (thin wall) CIPP liner. This would provide a barrier to stop the deterioration process. Rehabilitating a pipe with a structural grade of 5 will need to employ a fully deteriorated, designed liner, possibly in combination with an Excavation Point Repair to address serious localized deterioration.

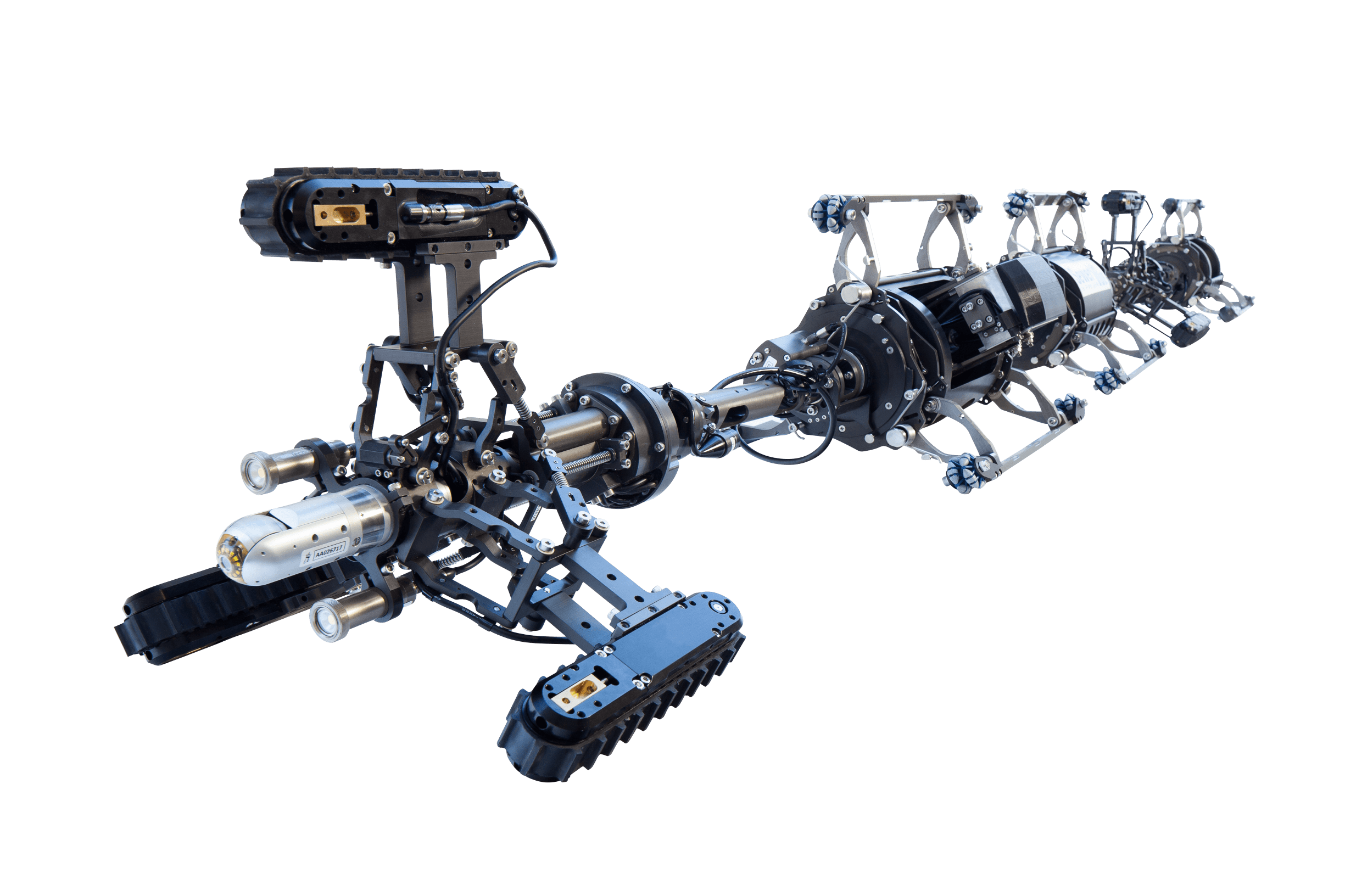

The Asbestos Cement Pipe Scanner

To take the quantitative measurements needed for a predictive model of these pipes, SewerVUE Technology designed and built the Asbestos Cement Pipe Scanner. The ACPS uses SewerVUE’s revolutionary pipe penetrating radar (PPR) technology to quantify the remaining wall thickness of 250 millimetre AC pipe. Early lab and field tests of this technology showed good results. In December 2017, the fully-constructed ACPS underwent its first test in a live pipe: the Harbourgreene Line in Surrey, British Columbia. The test was a total success. In its first deployment, and in the span of one short morning, the ACPS collected excellent PPR data from a live sewer pipe.