Reporting

Get The Data You Need With SewerVUE's Reporting

SewerVUE's industry-leading pipe inspection technology delivers unparalleled actionable, qualitative results that will assist you in assessing and maintaining your underground infrastructure. By utilizing multi-sensor and pipe-penetrating radar technology, SewerVUE's team can collect comprehensive data from within the pipes, offering the level of detail and accuracy necessary to make informed rehabilitation decisions. Our multi-sensor technology enables us to provide a complete view of both large and small-diameter pipes, identifying issues such as cracks, blockages, and structural defects with unmatched precision. Minimize costly disruptions and ensure long-term structural integrity with SewerVUE's condition assessment.

Sample Reports

View a SewerVUE multi sensor inspection report to get an idea of how we analyze and process data results. Understand how our PPR data can assist with your asset management. We provide precise, customized reporting for any SewerVUE project.

SewerVUE uses advanced pipeline inspection technology to survey pipes. The results can range from:

- CCTV PACP results

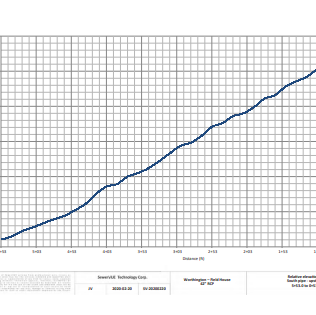

- Relative altitude results

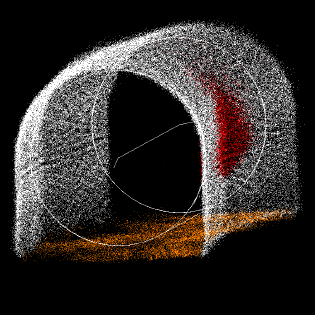

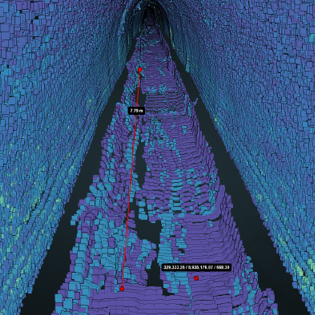

- 3D point clouds

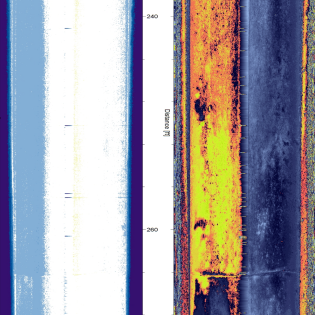

- Wall thickness measurements

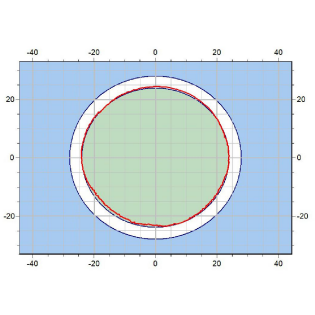

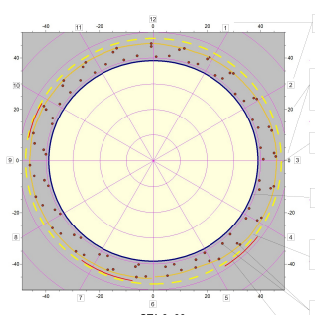

- Reinforcement cover measurements

This report contains the results of a multi-sensor inspection project. 255.5 metres of 750 and 900 mm reinforced concrete pipes were surveyed. This inspection was undertaken with SewerVUE's MPIS float system, utilizing LiDAR, sonar, and CCTV.

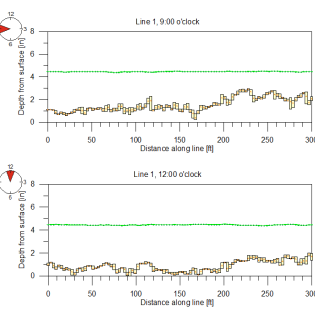

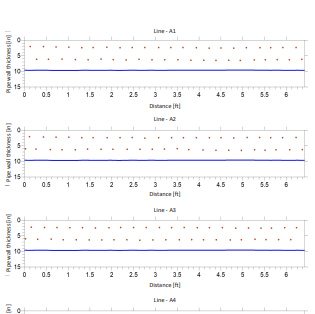

In-pipe technology was used to assess the condition of a recently-rehabilitated 34-inch high-density polyethylene sanitary sewer line. SewerVUE was commissioned to survey, locate and quantify defects within and around the pipe. The total inspection length was 935 metres. A remotely operated vehicle (ROV) equipped with CCTV, LIDAR, and PPR was deployed for this survey.

SewerVUE was commissioned to undertake a long range pipe inspection using pipe penetrating radar (PPR) survey of a newly rehabilitated HDPE main. The objective of the survey was to locate and quantify defects within and around the pipe. The total inspection length was 934 metres. A remotely operated vehicle (ROV) equipped with CCTV, LIDAR, and pipe penetrating radar (PPR) was deployed for this survey.