Toronto - October, 2020

Geolocation of a sanitary sewer pipe inside a storm pipe under one of the busiest intersections of Toronto, Canada

In October 2020, SewerVUE was commissioned by WSP Global Inc. to perform a geometric assessment of a 560m long, 3000 mm diameter combined sewer with a 675 mm sanitary pipe encased inside. The access to the project site was on the on-ramp of Hwy 401, one of the busiest exchanges in Toronto.

The Challenge

The City of Toronto’s objective was to locate, with pinpoint accuracy, the 3-axis alignment of the 675 mm sanitary pipe encased inside the 3000 mm storm pipe. The goal of the project was to create a 3D point cloud of the pipe to aid in the construction of a new shaft.

In addition to the access being within one of the busiest traffic corridors, the manway into the pipe was a 90-meter-deep shaft that necessitated the services of National Safety Scope; a dedicated confined space rescue team. The City of Toronto and WPS Global Inc. selected SewerVUE Technology to provide an advanced condition assessment of the pipe.

Daniel Tenney, a project engineer at WSP, who was directly involved during deployment at the Consumer’s road job, describes the overall mission as follows:

“We were looking for innovative companies that are capable to take on this project because it required sophisticated technology. Everybody at SewerVUE was easy to work with, the quality of deliverables was high, and was exactly what we were looking for. Overall, it was a great experience.”

The proposed solution

Figure 1. SewerVUE's Surveyor.

Figure 2. SewerVUE's Surveyor at the top of box culvert inside the pipe

“Due to the rainy weather in Toronto, it was challenging to lower the Surveyor robot 90 feet down into the access manhole as well as extracting it at the terminus point. Overall, the team did a great job operating the ROV considering they had to drive on a raised 30 inch platform.”

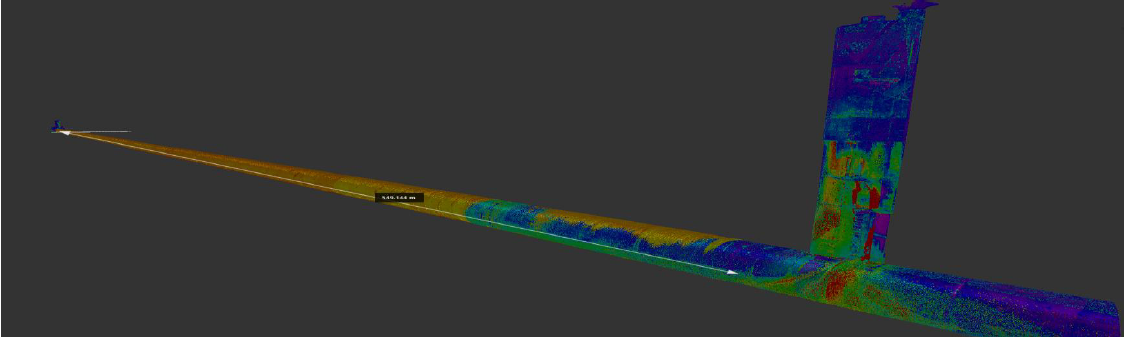

Data were collected from an array of sensors, including CCTV and 3D- LiDAR. The deliverables included a 3D point cloud of the pipe (Figure 3) to aid in the installation of a new shaft.

The Result

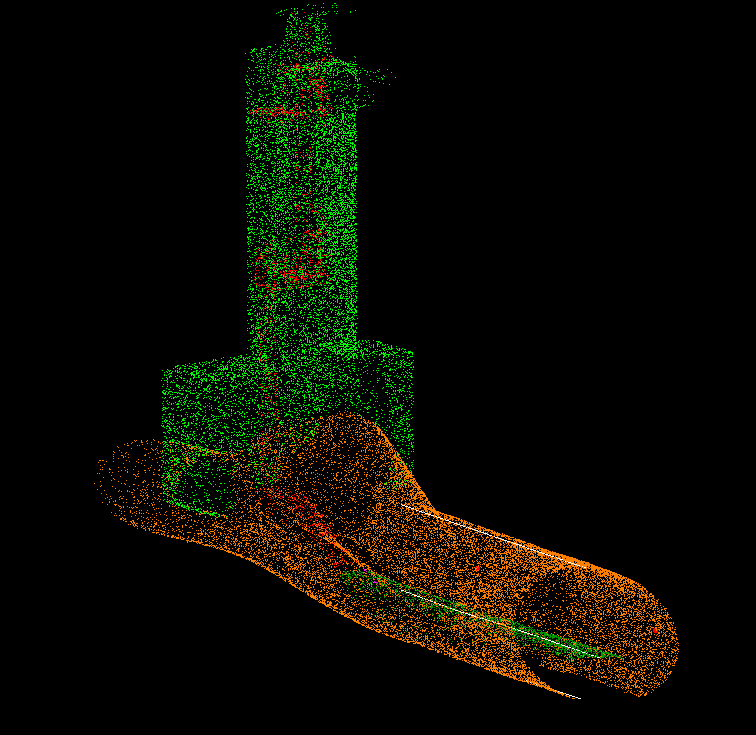

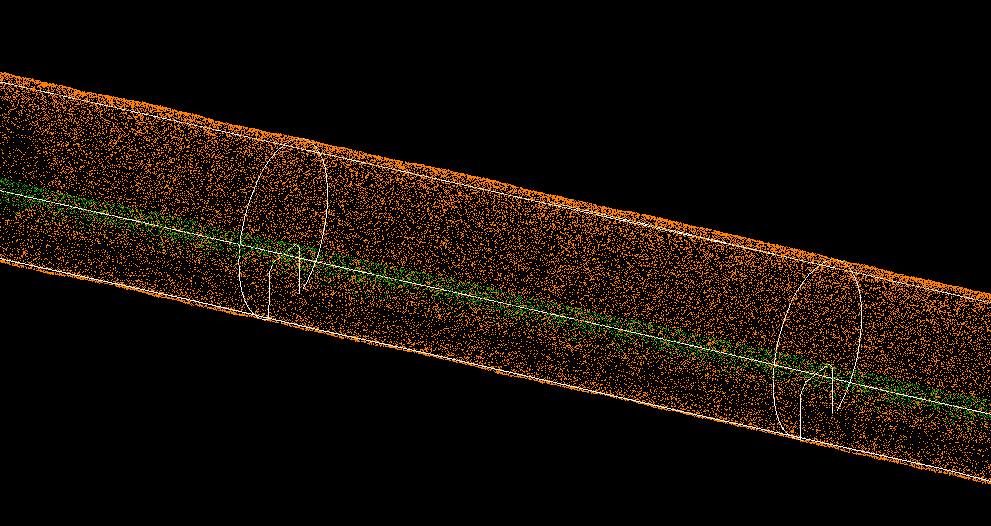

The multi-sensor inspection report consisting of LiDAR cross-sections, a foldout view, PACP coded defects, and a 3D point cloud representation of each section of the pipe was presented to WSP. IBW Surveyors, a professional surveyor contractor was hired to geo-reference the entrance and exit points of the 3D point cloud.

“IBW had a great experience working with the SewerVUE team on this pretty interesting and challenging project in Toronto. Even though we had a good plan on how to perform the work, the site conditions required our teams to discuss, troubleshoot, and come up with a different approach to tackle the project, making it an even more interesting project. The SewerVUE guys are true team players, and we look forward to working with them on future projects.”

Figure 3. The 3D point cloud of the pipe from the access to the terminus point.

These 3D point cloud results show defects and features of the pipe in color gradation. For example, the negative variance in the MSI charts represents a protrusion (e.g., a tap) into the pipe whereas the positive variance represents a depression-type feature (e.g., a plug). Black regions on the snakeskin chart indicate water. Samples of other deliverables are shown in Figures 4 and 5.

Figure 4. 3D Cross-Section drawings of pipe walls

Figure 5. 3D Cross-Section drawings of the access shaft.

To learn more about the SewerVUE technology for year-round advanced pipeline inspections, please visit our website at www.sewervue.com or contact us directly via email at sales@sewervue.com or telephone at (604) 421-0600.